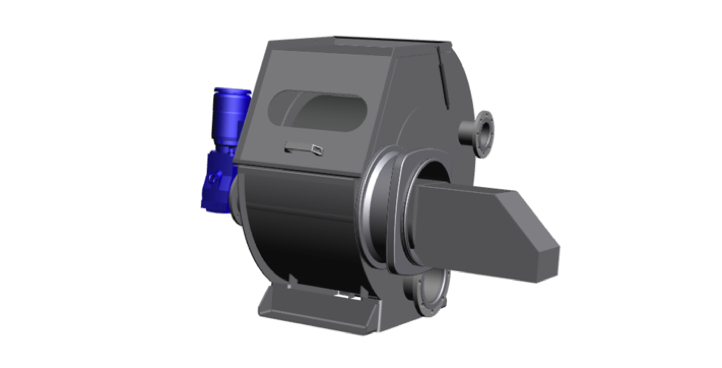

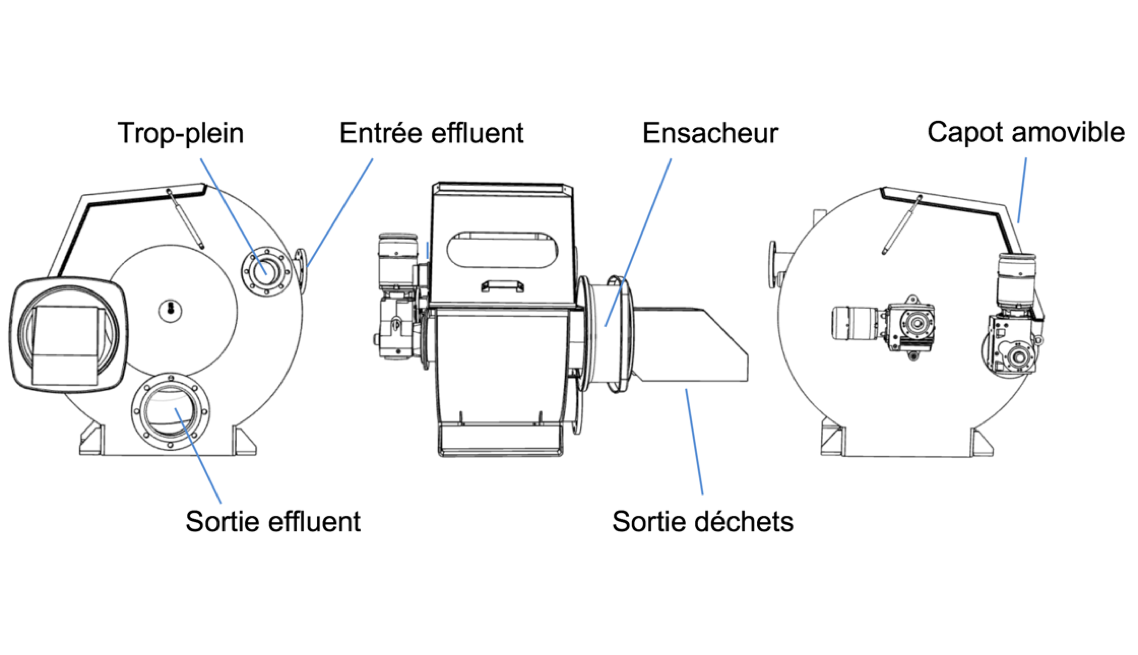

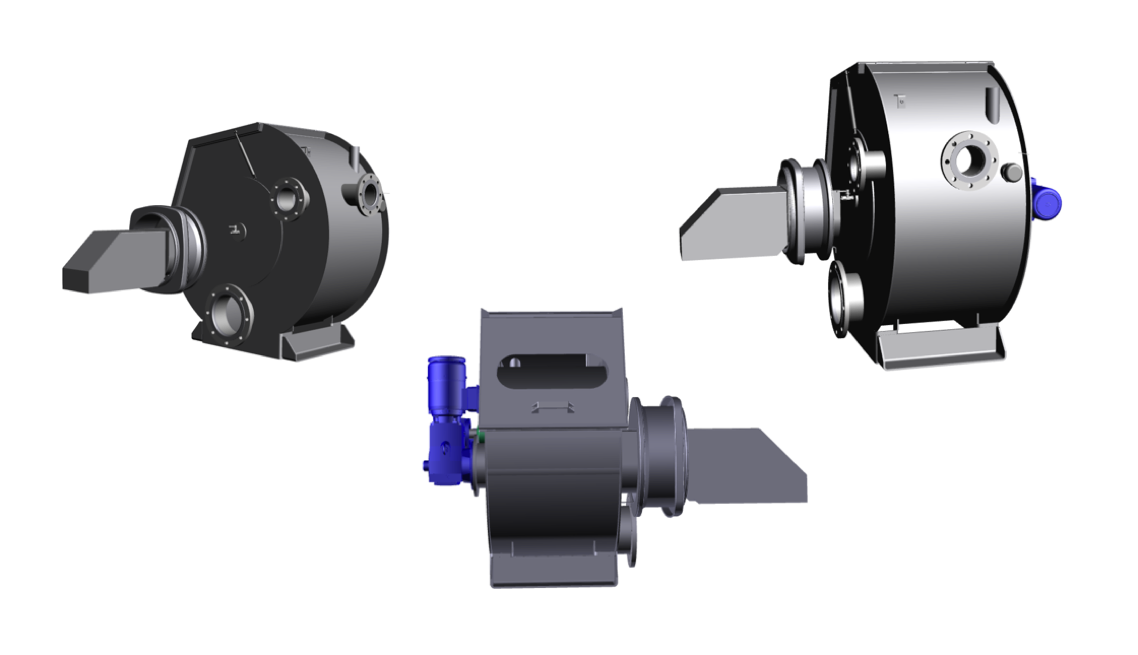

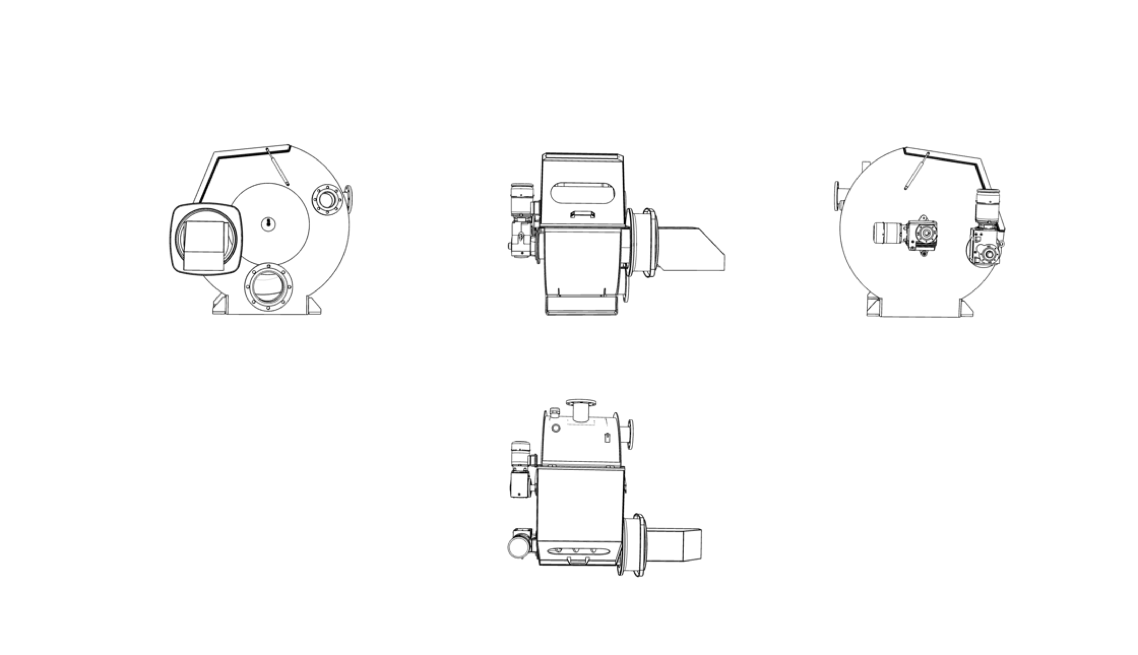

DRUMSEP /P SPECIFICITIES

DESCRIPTION / OPERATION

The rotary screens are connected to pumps outlet. Their objective is to achieve a fine separation of the waste contained in the effluent.

Originally developed for industrial and predominantly agri-food applications such as canneries and slaughterhouses, the use of this technology has been extended to pretreatment applications at sewage treatment plants.

The drum manufactured with a mesh size of 750 microns is often used to carry out all the pretreatment steps of the plant.

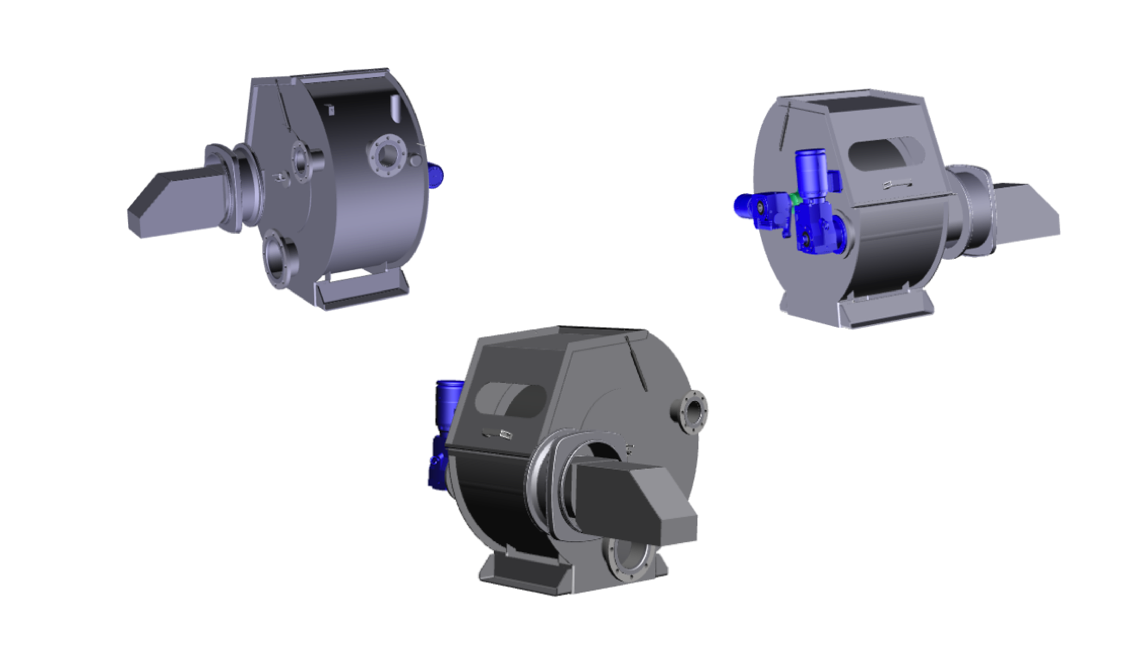

The combination of the ENVIROPRESS screw compactor with the rotating drum allows to produce a single dewatered waste. It is also possible to select a waste washing solution, which is available in the SPIRAPRESS range.

DESIGN

SCREENING

The cylindrical shaped grid consists of a wounded trapezoidal wire. The filter mesh is calibrated at the time of its manufacture.

The rotating drum is continuously cleaned and provides a permanent clean surface to the effluent. In its rotating motion, it drives waste on the other side where screenings are scraped to fall into the compactor.

WASHING RAMP

A high pressure washing ramp, in continuous operation, is positioned inside the drum. Thus, at each turn, a clean surface is available to the incoming effluent.

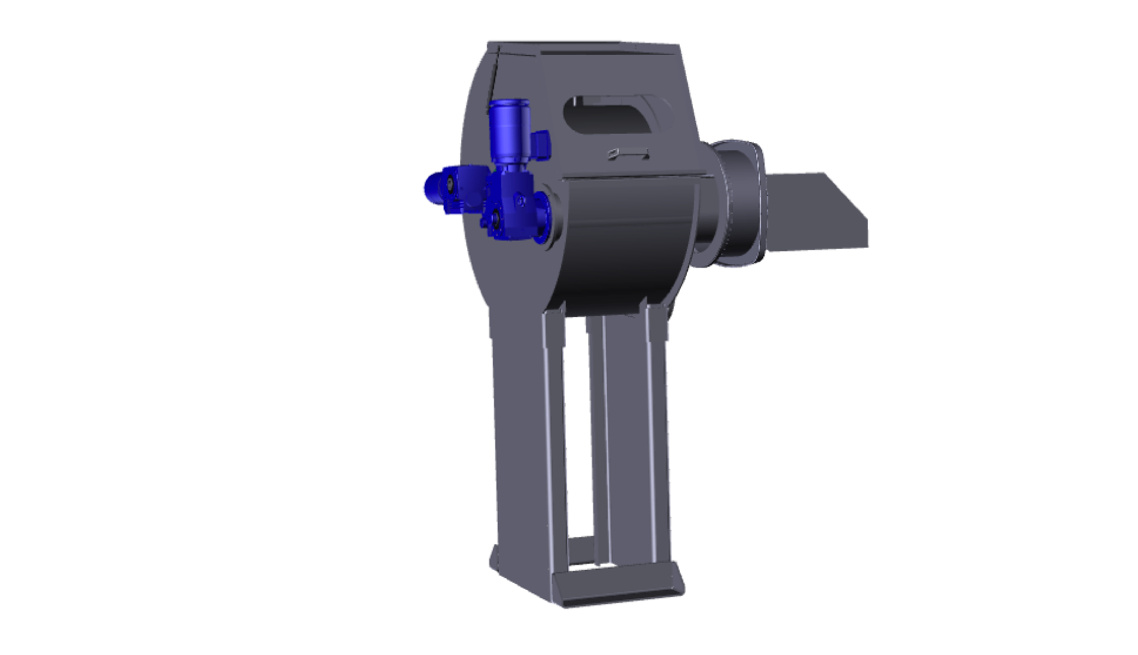

TRANSPORT

The shaftless screw collects the waste, screened by the rotating drum, and drives it towards the compactiing chamber (ENVIROPRESS version)

COMPACTING

An innovative counterpressure system CONIXPRESS allows to adapt to the nature of the waste, and to maintain a balance between optimum compacting and regular evacuation of the waste.