SPIRASCREEN /P SPECIFICITIES

DESCRIPTION / OPERATION

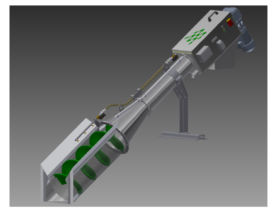

The screening-compacting SPIRASCREEN series SRS/P using shaftless screw is particularly adapted to project where effluent is delivered by gravity. The unit insures screening, conveying, and solid waste compacting functions.

However, to match with specific applications or installations, it is possible to remove the compacting zone (model SRS) and to connect one or several parallel units to an ENVIROPRESS screw compactor model.

The effluent is flowing through the filtration grid where solid waste is stopped and removed under the action of the conveying shaftless screw towards the upper part to be discharged. Up to 1000 m3/h can be processed per unit.

DESIGN

SCREENING

The effluent is processed through the cylindric filtration grid. Due to such design, the effective filtration area is much larger compare to flat screening technology. Therefore, the ratio between size/flow allows to reduce the overall dimensions of the unit. Brushes are fixed onto the shaftless screw in order to keep the filtration zone clean and flow efficient by rotation during operation.

CONVEYING

The screw is extended to the conveying zone and then to the compacting zone before solid waste discharge.

COMPACTING

On the upper part, the solid waste is compacted in order to remove water and reduce the volume.

WASHING RAMP

In order to reduce the organic content present in the solid waste, washing ramps can be installed at the screeening and conveying zones.

WASTE

The screening waste can be either discharged directly into containers or conditionned in continuous closed plastic bagging unit.