SEPTISPIR SPECIFICITIES

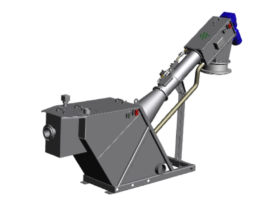

DESCRIPTION / OPERATION

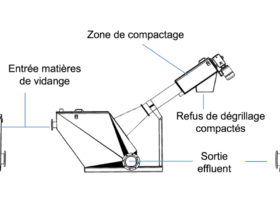

Liquid waste from septic tanks are pumped by specially equipped trucks and are then transported them to the treatment centers. They are sent back to the SEPTISPIR screen- compactor in order to carry out the “Liquid/Solid” separation. The connection to the machine is made by quick coupling. While the liquid part passes through the screen, the solids are extracted by the screw and lifted towards the compaction zone in order to be compressed therein.

This compact version is proposed for installation in height. To match with specific applications or installations, it is possible to remove the compacting zone (model SRS) and to connect one or several parallel units to an ENVIROPRESS screw compactor model.

DESIGN

SCREENING

The effluent from scepic tanks drainage is processed through the cylindric filtration grid. Due to such design, the effective filtration area is much larger compare to flat screening technology. Brushes are fixed onto the shaftless screw in order to keep the filtration zone clean and flow efficient by rotation during operation.

CONVEYING

The screw is extended to the conveying zone and then to the compacting zone before solid waste discharge. Length is adjustable on case by case basis.

COMPACTING

On the upper part, the solid waste is compacted in order to remove water and reduce the volume.

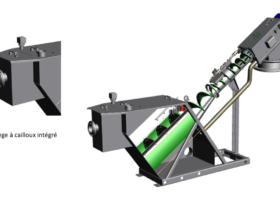

WASHING RAMP

In order to reduce the organic content present in the solid waste, a washing ramp is installed along the screeening zone. An additionnal washing ramp, in otion, can be installed along the conveying zone as well.

WASTE

The screening waste can be either discharged directly into containers or conditionned in continuous closed plastic bagging unit.